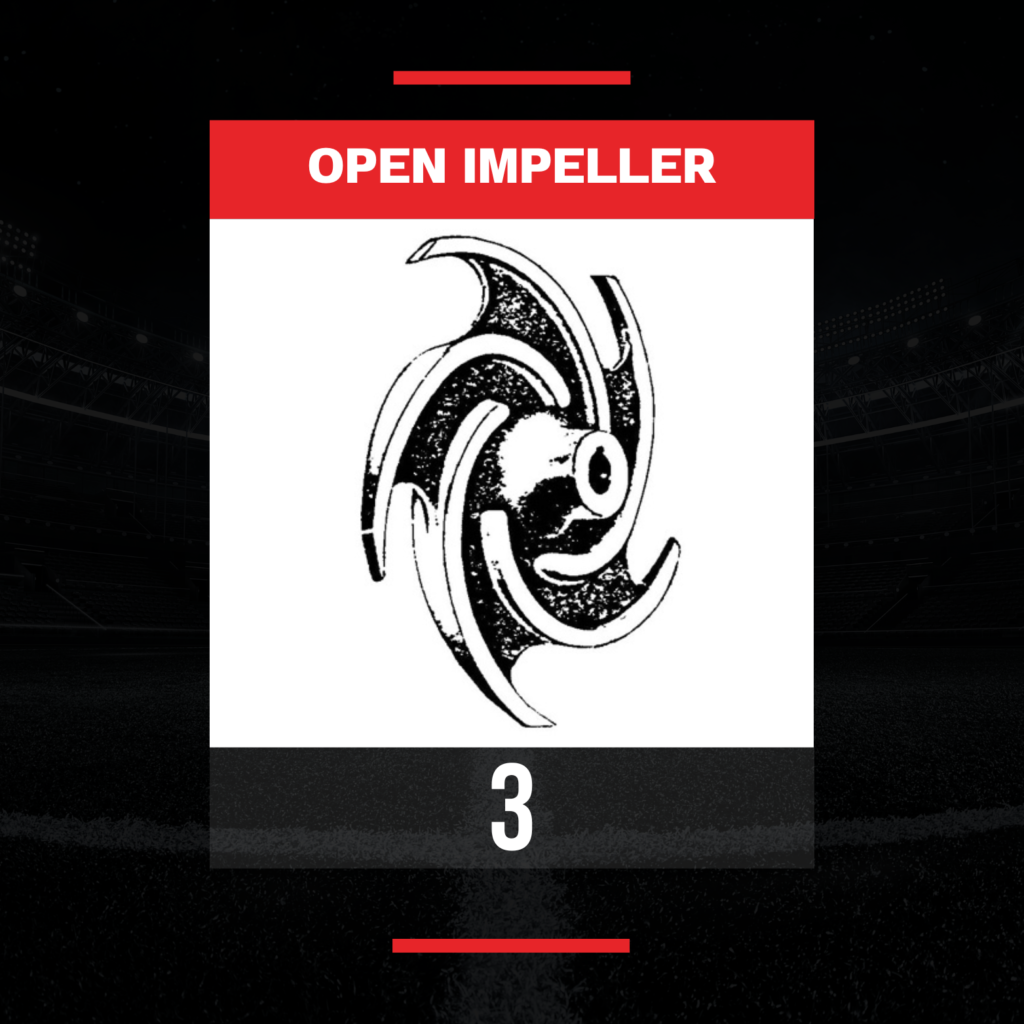

The operation of the centrifugal pump impeller must consist of a combination of several parts. One of the components or parts that is an important part is the impeller. It can be divided into 3 types: Open Impeller, Semi-Open Impeller, Closed Impeller.

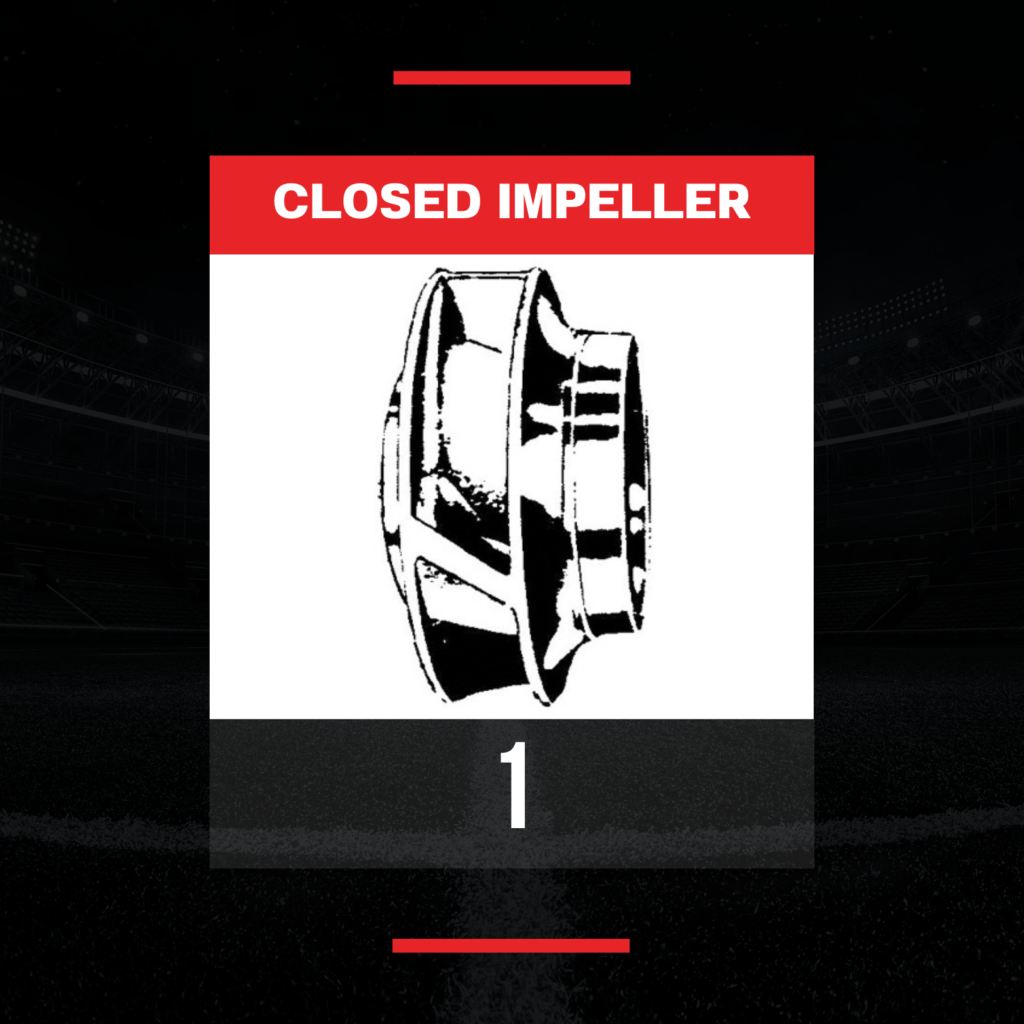

1. Closed Impeller:

A closed impeller has vanes that are fully enclosed between two discs, forming a continuous flow path. The fluid enters the impeller through an inlet and is forced outward by the rotating vanes, generating pressure. Closed impellers are used in high-pressure applications where efficiency and precise fluid handling are crucial. They are commonly found in multistage centrifugal pumps and applications that require high heads or pressures.

A semi-open impeller has vanes that are attached to a central hub, similar to an open impeller. However, in a semi-open impeller, one side of the vanes is enclosed by a back or shroud plate, while the other side is open. The fluid enters through the open side of the impeller and is discharged through the vanes. Semi-open impellers are commonly used in applications where the pumped fluid contains solids or debris that could potentially clog the impeller.

3. Open Impeller:

An open impeller is a type of centrifugal pump impeller with vanes that are not enclosed between two discs. The vanes are attached to a central hub, and the fluid flows through the passages between the vanes. Open impellers are typically used in low-pressure applications and are suitable for handling fluids with solids or fibrous content. They are relatively easy to manufacture and maintain.

It’s important to note that these impeller types can vary in design and specific features depending on the manufacturer and the application requirements.

YOUTUBE : YONGHONG