A machine that gives you the best finish you’ve ever seen! Based on a totally new concept, the NP80A is designed to be user-friendly, easily maintained and completely reliable. A machine you can really trust. Easy to use, high productivity, excellent portability. A machine that gives you total control and satisfaction on the job.

Special features of REX Pipe Threading Machines

In addition to their precision, toughness and variety, Rex pipe threading machines offer these great features.

Consumables can be replaced easily.

EASY MAINTENANCE

– Easy to change the Dies

– Easy to change the Chuck Jaw Inserts

– Easy to check and inspect the Oil Pump, too

– Easy to change the Carbon Brushes

COMPATIBILITY

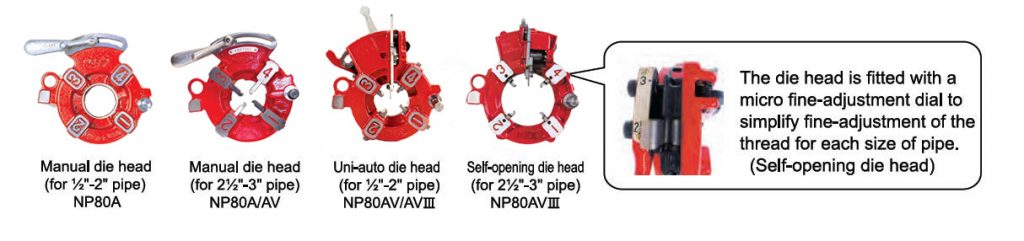

While there are differences in the types of die head,

the dies for 1½” to 4″ machines are mostly interchangeable.

● The ½” to 2″ Manual DH, Uni-auto DH, NV-auto DH and

Self-opening DH are compatible with the 50A, 80A and 100A.

● You can also attach REX portable groovers.

● The cutter wheels for the 40A, 50A, 80A,

100A and 150A are compatible.

USER FRIENDLY

Standard Accessories:

∙ Carbon Brushes 1 pair, Cutting Oil (50W-R) 4 L

∙ Hex key-wrench 3-4-5-6 mm, Dies ½”-¾”, 1″-2″, 2½”-3″ 1 set each

∙ Die Head ½”-2″, 2½”-3″ one each

| Model | Pipe size | Voltage | Motor (W) | Speed | Weight | Size (mm.) | ||

| (V) | ( Hz) | In | out | Width x length x height | ||||

| NP80A | 1/4“-3” | 220V | 50/60 HZ | 1600W. | 1000W. | 29 RPM | 67kg. | 490x690x423 |