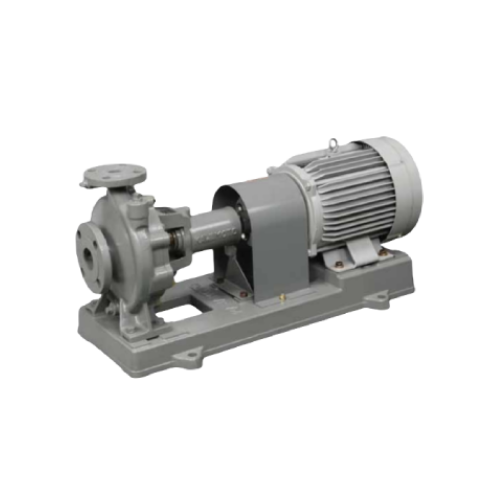

Centrifugal Pump KAWAMOTO GE-2M Series

End Suction Centrifugal Pump KAWAMOTO Model GE-2M that is suitable for a range of applications such as water circulation, cooling water, agriculture, and industry. This pump is compact and lightweight, making it easy to maintain and inspect due to its back pull-out construction. It also features a long-life mechanical seal for shaft sealing and a simple end suction top centerline discharge position, allowing for steady installation with high discharge pipe loading. Additionally, the KAWAMOTO Model GE-2M complies with Japanese industrial standards (JIS B8313) and can be used for various purposes, except for drinking water (please inquire separately for this application).

Facebook

Twitter

Email

Print

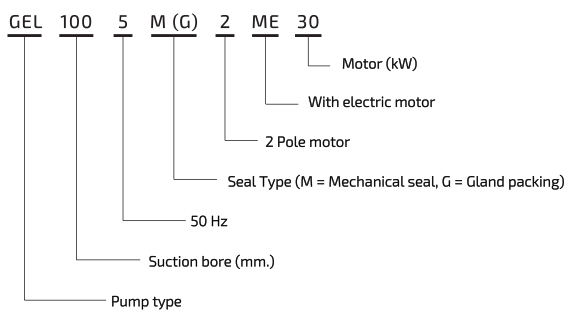

Model GE-2M

End Suction Centrifugal Pump KAWAMOTO

2 Poles / 50 Hz SIZE 40-100 mm

APPLICATIONS

- Cold and hot water circulation

- Cooling water for building and factory equipment

- Agriculture

- Industry

- Other general water supply (Please inquire in case drinking water application)

FEATURES

- Compact and light weight.

- Easy maintenance and inspection due to back pull out construction.

- Long life mechanical seal is adopted for shaft sealing.

- Simple end suction top centerline discharge position enable steady installation with high discharge pipe loading.

- Wide application for various usages.

- In accordance with Japanese industrial standard (JIS B8313).

STANDARD SPECIFICATIONS

| Description | Model :GE-2M | |

|---|---|---|

| Liquid | Name | Clean water |

| Temperature | 0~90°C | |

| Max Working Pressure | 10 bar | |

| Synchronous Speed | 3000 min-1 | |

| Installation | TEFC outdoor use (Motor IP55, Class F) | |

| Material | Casing | Cast iron (FC200) |

| Impeller | Cast iron (FC200), Bronze (CAC406) or Stainless Cast iron (SCS13) | |

| Shaft | Stainless steel (SUS403) | |

| Construction | Impeller | Closed |

| Shaft Seal | Mechanical seal (SIC x Carbon x FKM ) | |

| Gland packing (PTFE-non asbestos) | ||

| Sealing | None | |

| Bearing | Sealed ball bearing | |

| Flange | JIS10K | |

| Baseplate | Cast iron (FC150) | |

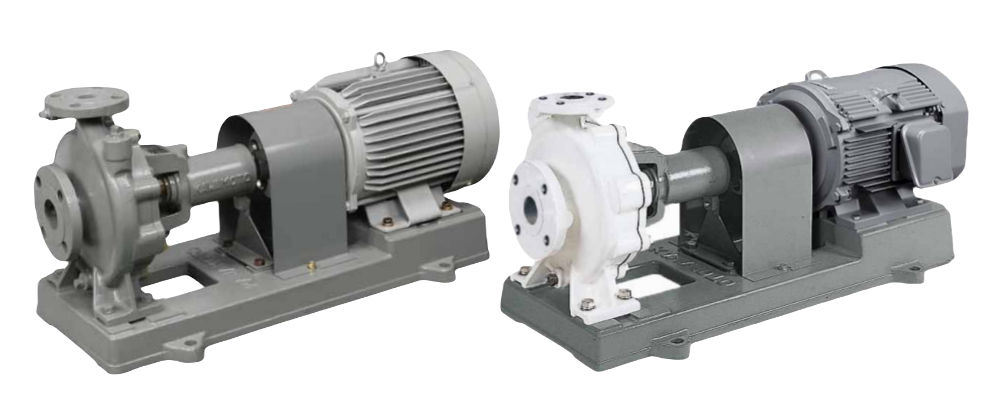

OPTIONAL SPECIFICATIONS

| Description | Model: GE-2M | |

|---|---|---|

| Material | Casing | Cast iron + Nylon coating |

| Impeller | SCS14 (SUS316) 40x32 : 0.4-2.2kw 50x40:0.4-5.5kw 65x50:2.2-3.7kw 80X65 : 2.2~7.5kw 100x80 : 7.5-11kw | |

| Shaft | Stainless steel (SUS316) | |

| Construction | Impeller | Closed |

| Shaft Seal | Mechanical seal (SIC x SIC x FKM ) | |

| Sealing | None | |

| Bearing | Sealed ball bearing | |

| Flange | JIS 10K | |

| Baseplate | Channel baseplate for European motor bland | |

| Anti-corrosion Painting | Urethane resin coating + non touch seal bearing structure | |

| Epoxy resin coating | ||

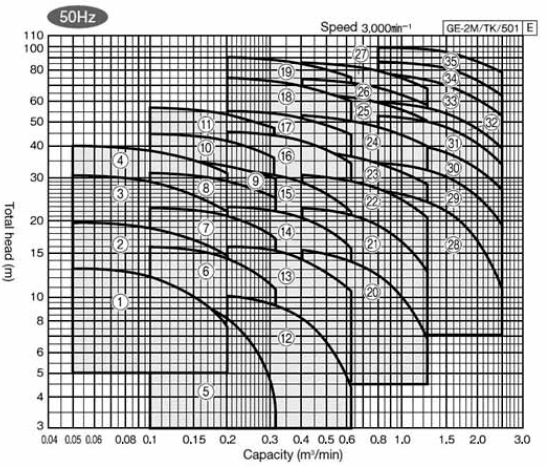

SPECIFICATION TABLE

| No. | Model | Motor (kw) | Performance | Back Pressure Mpa {kgf/cm2} | |||

|---|---|---|---|---|---|---|---|

| Capacity (m3/mn) | Head (m) | Capacity (m3/mn) | Head (m) | ||||

| 1 | GEH-40X325M 2MN0.4 | 0.4 | 0.05 | 13 | 02 | 7.5 | 089 |

| 2 | GEI40SM2MEO 75 | 0.75 | 0.05 | 19.8 | 02 | 14.5 | 0.77 |

| 3 | GEI405M2ME15 | 15 | 0.05 | 30 5 | 02 | 22 | 067 |

| 4 | GEJ40SM2ME2.2 | 2.2 | 0.05 | 40 | 02 | 31.5 | 0.58 |

| 5 | GCH-50X405M-2MN0.9 | 0.9 | 0.1 | 10.5 | 0.32 | 3.5 | 0.86 |

| 6 | G6H505M2ME0.75 | 0.75 | 0.1 | 15.8 | 0.32 | 10.5 | 0.81 |

| 7 | GEI5O5M2ME1.5 | 15 | 0.1 | 22 5 | 0.32 | 17 | 0.74 |

| 8 | G6J505M2ME2.2 | 2.2 | 0.1 | 31 | 0.32 | 29.5 | 0.67 |

| 9 | GEJ50SM2ME3.7 | 3.7 | 0.1 | 35.5 | 0.32 | 29.8 | 0.63 |

| 10 | GEK5O5M2ME3.7 | 3.7 | 0.1 | 44.5 | 0.32 | 35.5 | 0.52 |

| 11 | GEK5O5M2ME5.S | S.S | 0.1 | 565 | 0.32 | 97 | 0.39 |

| 12 | GEH655M2ME0.75 | 0.75 | 02 | 10 | 0.63 | 9.2 | 0.87 |

| 13 | GEH6SSM2ME1.5 | 1.5 | 02 | 15.8 | 0.63 | 10.5 | 0.81 |

| 14 | GEI655M2ME22 | 2.2 | 02 | 22.8 | 0.63 | 152 | 0.74 |

| 15 | GEJ655M2ME3.7 | 3.7 | 02 | 325 | 0.63 | 21 | 0.6 |

| 16 | GEK65SM2ME5.S | 5.5 | 02 | 95 | 0.63 | 34 | 0.52 |

| 17 | G6K655M2ME7.5 | 7.5 | 02 | 59.5 | 0.63 | 43.5 | 0.92 |

| 18 | GEL655M2ME11 | 11 | 02 | 75 | 0.63 | 595 | 0.22 |

| 19 | GEL655M2ME15 | 15 | 02 | 90 | 0.63 | 74 | 0.059 |

| 20 | GEH805M2ME2.2 | 2.2 | 0.4 | 152 | 1.25 | 6.5 | 0 81 |

| 21 | CE1805M2ME37 | 3.7 | 0.4 | 22.5 | 1.25 | 12 | 0.74 |

| 22 | GEJ80SM2MES.5 | 5.5 | 0.4 | 305 | 1.25 | 20 | 0.66 |

| 23 | GEI805M2ME75 | 7.5 | 0.4 | 385 | 1.25 | 27.5 | 0.58 |

| 24 | GEK80SM2ME11 | 11 | 0.4 | 52 | 1.25 | 38.5 | 0.95 |

| 25 | GEK805M2ME15 | 15 | 0.4 | 635 | 125 | 49 5 | 0.33 |

| 26 | GEL8O5M2ME18 | 18.5 | 0.4 | 74 | 1.25 | 57 | 0.32 |

| 27 | GEL8O5M2ME22 | 22 | 0.4 | 85 | 1.25 | 67 | 0.13 |

| 28 | GEI1005M2ME7.5 | 7.5 | 0.8 | 26.5 | 2.5 | 10.5 | 0.69 |

| 29 | GEJ100SM2ME11 | 11 | 0.8 | 34 | 25 | 19 | 0 62 |

| 30 | GEI1005M2ME15 | 15 | 0.8 | 92 | 2.5 | 27 | 0.59 |

| 31 | GEK1005M2ME18 | 18.5 | 0.8 | 52.5 | 25 | 33 | 0.44 |

| 32 | GEK10O5M2ME22 | 22 | 0.8 | 59 | 25 | 385 | 0.37 |

| 33 | GEL100SM2ME30 | 30 | 0.8 | 76 | 25 | 51.5 | 0.22 |

| 39 | GE11005M2ME37 | 37 | 0.8 | 86 | 25 | 64 5 | 0.098 |

| 35 | GEL1O05M2ME95 | 95 | 0.8 | 99 | 25 | 77 | 0 |