Safety Colors

Safety colors are colors that are used to convey specific messages related to safety in the workplace. The use of safety colors is an important aspect of workplace safety because it can help prevent accidents, injuries, and even fatalities.

| Colors | Meaning | Function | Background |

| Red | Stop |

1.Location of fire 2.Prohibition |

White |

| Blue | Compulsory |

1.Mandatory signs 2.Warning signs |

White |

| Green | Glue Security |

1.Security situations 2.Emergency room 3.First aid |

White |

| Yellow | beware of danger |

1.Indicates that there is a danger, such as fire, explosives. 2.Indicates the danger zone. dangerous passage barricade |

White |

It is important to use safety colors consistently and appropriately throughout the workplace to ensure that workers understand the messages being conveyed and can respond appropriately to potential hazards or emergencies.

Safety sign

Safety signs are visual cues used to convey important safety information to people in a variety of settings, such as workplaces, public areas, and roads. These signs are designed to quickly communicate potential hazards, instructions, or precautions to help prevent accidents and injuries.

| Shape | Meaning |

Colors |

Background |

Symbol color picture |

Example of function |

|

|

Prohibit |

Red |

White |

Black |

|

|

|

Compulsory |

Blue |

White |

White |

|

|

|

Warning |

Yellow |

Black |

Black |

|

|

|

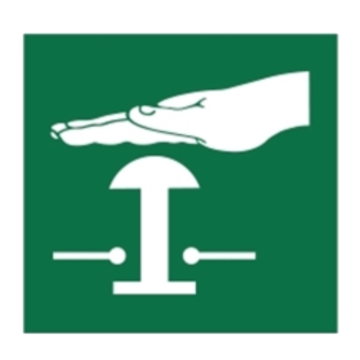

Security situations |

Green |

White |

White |

|

|

|

Fire Equipment |

Red |

White |

White |

|

It’s important to pay attention to safety signs and follow their instructions to minimize the risk of accidents and injuries. Employers and facility managers are responsible for ensuring that proper safety signs are posted in visible locations and that employees and visitors are aware of their meanings.

Factory safety is an essential aspect of workplace safety, and it involves measures and procedures that ensure the health, safety, and well-being of employees and other individuals who work in or visit the factory premises. Ensuring factory safety is crucial because factories often have hazardous machinery, chemicals, and materials that can pose significant risks to workers’ health and safety if not handled properly.

Here are some measures that can be implemented to ensure factory safety :

- Implement safety policies : Establish and enforce clear safety policies that include rules and guidelines for handling hazardous materials, operating machinery, and responding to emergencies.

- Provide safety training : Provide regular safety training to all employees on the proper handling of machinery, tools, and equipment, and the correct use of protective gear.

- Conduct regular safety inspections : Regularly inspect the factory premises, equipment, and machinery to identify and address potential safety hazards.

- Install safety equipment : Install safety equipment such as fire alarms, sprinklers, and extinguishers to prevent and manage fire hazards.

- Provide personal protective equipment (PPE) : Provide PPE such as gloves, safety glasses, hard hats, and respirators to employees working in hazardous areas or handling dangerous materials.

- Maintain machinery : Regularly maintain and repair machinery to ensure it is in proper working condition.

- Monitor chemical exposure : Monitor and control exposure to hazardous chemicals by enforcing the use of proper ventilation, limiting exposure time, and providing proper training.

Implementation of these measures in factories where equipment is used Working machinery such as electric chain hoists, structural cranes in moving heavy objects The more you understand the symbols in your factory, the more likely you are to reduce the risk of accidents, injuries, and fatalities. And it creates a safer working environment for employees.

Performance : electric chain hoists, structural crane

Circular bar with oblique bar

Circular bar with oblique bar Circle

Circle

Equilateral triangle

Equilateral triangle

Square

Square

Square

Square