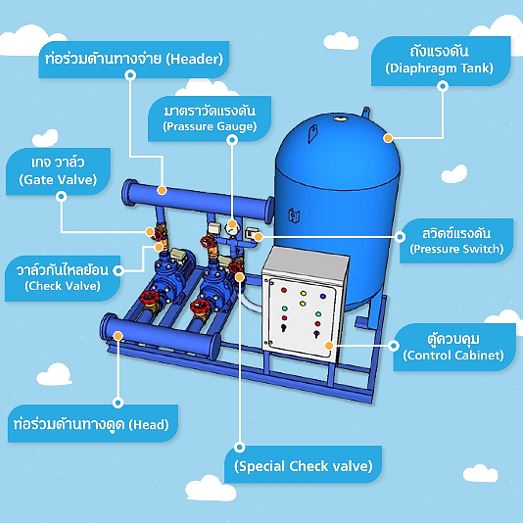

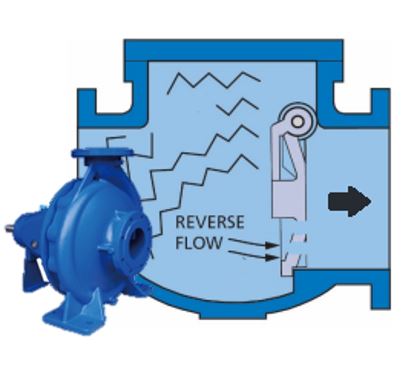

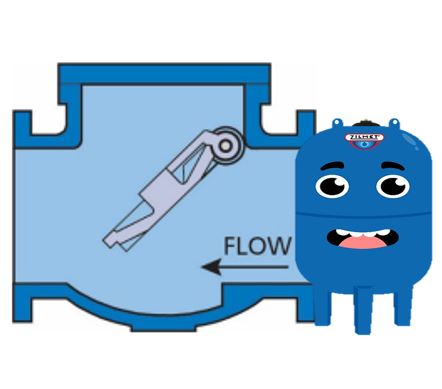

Special check valves are often used in the booster pump set, whereby the work is that the valve will drill holes to allow water to pass through both directions. Instead, it slows the flow of water through the shoulders. Reduce shocks and sudden pressure changes. And will be installed in the pipe that pumps water into the pressure tank will insert the check valve in reverse and drill a hole In order for the water to enter the pressure tank slowly, preventing the internal diaphragm or bladder from rupturing, but when dispensing, must be paid quickly. to meet the needs of users

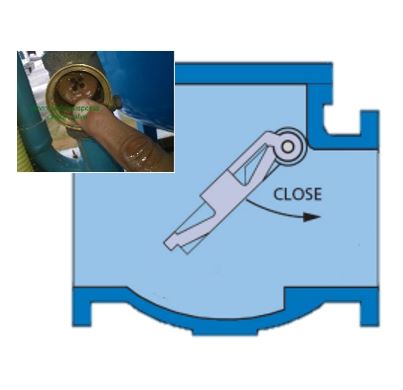

The flow of water from the pump pumped into the pressure tank. causing the check valve to close.

In the pipe to the pressure tank, a special check valve is installed that has a hole to allow water to enter the pressure tank slowly.

In the pipe line out of the pressure tank is a check valve that pushes water from the tank that needs to supply water. according to the need for use.

The advantages of Special check valves are as follows

- Customization : Special check valves are designed and manufactured to meet specific requirements or specific applications on each site. This fine-tuning allows for a working method that is precisely tailored to the operation of each system. Valves can be optimized for factors such as flow rate, pressure and temperature.

- Improved Performance : Engineered specifically for applications, Special check valves can provide better performance compared to standard valves. Designed to handle flow characteristics unlike standard valves. This can result in better system performance. reduce energy consumption and increase overall efficiency

- Integration with other systems: Special check valves can be customized to ensure compatibility with existing equipment systems. This includes considerations such as connection type. Flange standards, sizes and materials used in construction Special check valve

- Security and Compliance: In some industries or applications It is important to comply with specific safety standards or regulatory requirements. Special check valves can be designed to meet these standards and guarantee the safe operation of the system. This may include features such as error protection mechanisms. Ability to shutdown in an emergency or compliance with industry-specific guidelines.

- Value: Although specialized check valves may cost more compared to standard valves, they are cost effective. But it can provide value in the long run. By complying with the system requirements It reduces system risks and downtime. This leads to total cost savings in terms of maintenance, repairs, energy consumption. and loss of productivity

It is important to note that the advantages of Special check valves may vary depending on individual applications and customization requirements. It has to be tailored to each system between vendors or specialized engineering firms. To ensure the performance of the Special check valve for each design system.

Watch video : Booster Pump