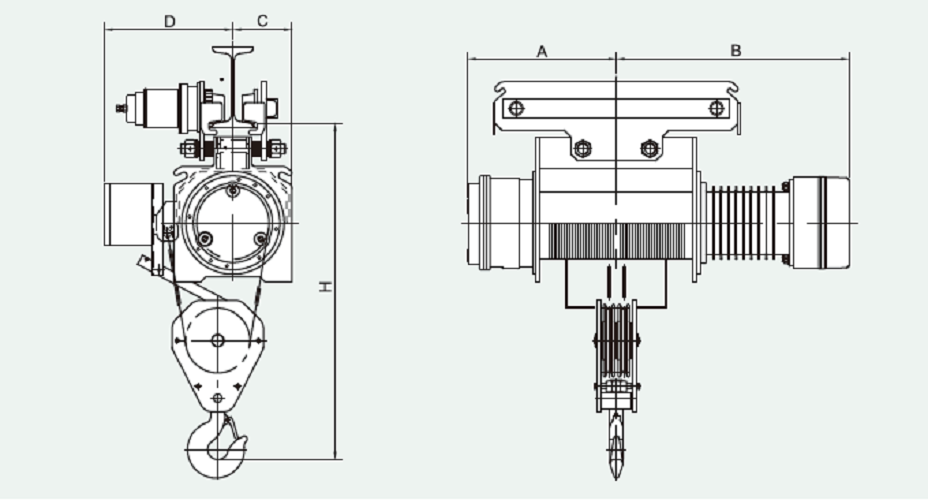

Electric wire rope hoist BLACKBEAR TB Series (AC Brake)Electric wire rope hoist BLACKBEAR MONORAIL TROLLEY AC Brake Electric wire rope hoist high quality products imported from Taiwan with AC Motor brack , is a Monorail Trolley type,has capacity load 5-10 Tons with single speed and Dual speed, (Up-Down-Left-Right)

Electric wire rope hoist BLACKBEAR MONORAIL TROLLEY AC Brake TB Series

Electric wire rope hoist BLACKBEAR TB AC Brake Electric wire rope hoist BLACKBEAR MONORAIL TROLLEY AC Brake use AC Electromagnetic safety brake.Besides low noise basic request, it’s with big brake torque, long life span.Its features come from multi-coil technology instead of the single structure as well as wear-resistant rotor capability to achieve the torque requirements for users.

| Model | Capacity (ton) |

Lift (m) |

Hoisting | Traversing | Wire Rope | Approximate Dimension (mm) | Approximate Weight (kg) |

|||||||||||||||||

| Speed(m/min) | Motor kw pole |

ED% | Speed(m/min) | Motor kw pole |

ED% | Ø mm | R/F | H | A | B | C | D | Adjust for Std. I-Beam (mm) |

|||||||||||

| 60Hz | 50Hz | Single | Dual | 60Hz | 50Hz | Single | Dual | Single | Dual | Single | Dual | Single | Dual | |||||||||||

| TBH-500 | 5 | 6 | 7.3 | 6.1 | 7.5 4 P |

40 | 40/20 | 18 | 15 | 0.6 4 P |

40 | 40/20 | Ø 10 | 2/4 | 1250 | 553 | 776 | 946 | 220 | 255 | 488 | 488 | 125-175 | 590 |

| TBHD-500 | 9 | 7.3/2.4 | 6.1/2.0 | 7.5/2.4 4/12P |

18/6 | 15/5 | 0.6/0.2 4/12P |

603 | 826 | 996 | 630 | |||||||||||||

| 12 | 743 | 966 | 1135 | 710 | ||||||||||||||||||||

| TBH-750 | 7.5 | 6 | 7.3 | 6.1 | 11 4p |

40 | 40/20 | 20 | 17 | 1.1 4 P |

40 | 40/20 | Ø 14 | 2/4 | 2000 | 608 | 921 | 1000 | 240 | 240 | 612 | 612 | 150-200 | 990 |

| TBHD-750 | 9 | 7.3/2.4 | 6.1/2.0 | 11/37 4/1 2P |

20/6 | 17/6 | 1.1/0.37 4/12P |

743 | 1056 | 1135 | 1020 | |||||||||||||

| 12 | 833 | 1146 | 1225 | 1060 | ||||||||||||||||||||

| TBL-1000 | 10 | 6 | 5.0 | 4.2 | 11 4p |

40 | 40/20 | 18 | 15 | 0.75X2 4 P |

40 | 40/20 | Ø 16 | 1/4 | 2000 | 605 | 903 | 982 | 340 | 340 | 640 | 725 | 150-200 | 970 |

| TBLD-1000 | 9 | 5.0/1.7 | 4.2/1.4 | 11/37 4/1 2P |

18/6 | 15/5 | 0.75/0.25X2 4/12P |

573 | 917 | 1050 | 640 | 725 | 1000 | |||||||||||

| 12 | 773 | 1017 | 1150 | 585 | 625 | 1040 | ||||||||||||||||||