Submersible Pump HCP AF Series

IMPELLER TYPE

P Type Impeller

Semi-open (Single Vane Impeller): Excellent to use with waste materials to prevent from clogging.

U Type Impeller

Semi-open(Vortex Impeller): produces a vortex (whirlpool effect) allowing long fibrous materials and other solid waste to pass through without contact with the

E Type Impeller

Enclosed Channel impeller: High impeller efficiency and clogresistant design, primarily used for large pump applications.

| Diameter (mm) | Description | ||

| Liquid temp. | 0-40°C(32~104°F) | ||

| Liquid natuer | Wastewater • Sewage | ||

| Max depth | 30m (100 feet) | ||

| Pump sect. | Structure | Impeller | Semi-open • Vortex |

| Mech seal | Double M. seals | ||

| Bearing | Ball type | ||

| Material | Upper cover | FC-200 | |

| Casing | FC-200 | ||

| Impeller | FC-200 | ||

| M. seal | Lower Sic/Sic • Upper: CA/CE | ||

| Motor sect. | Motor | Dry motor | |

| 4P (3600RPM) | |||

| Insulation | B Class (5HP:F Cass) | ||

| Frequency | 60Hz | ||

| Aoto-cut | Auto-cut | ||

| Material | Frame | FC-200 | |

| Main shaft | SUS420J2 (0.5-1HP : SUS403) | ||

| Cable | VCT or HO7RN-F or SJOW/SOWT | ||

| Pole | Model | HP(kW) | Discharge Inch(mm) |

Phase Ø |

Start Method |

Head m |

Capacity | Head feed |

Capacity GMP |

Weight kg (b) 1/3 |

Solid Passage mm |

Dimension (mm) | ||

| Length | Width | Height | ||||||||||||

| m³/min | ||||||||||||||

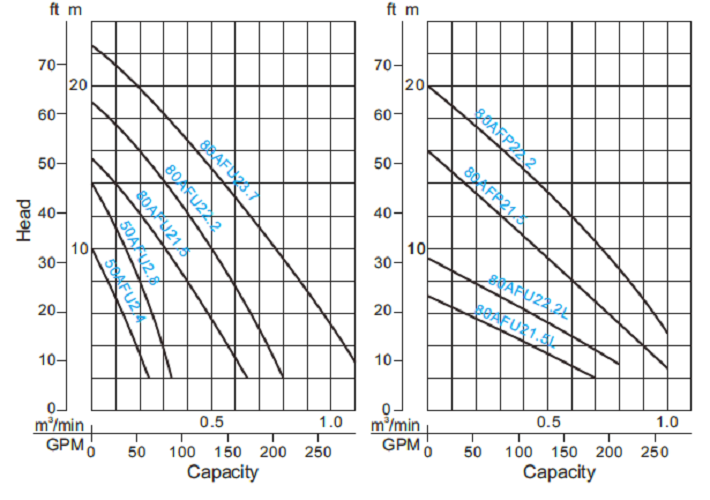

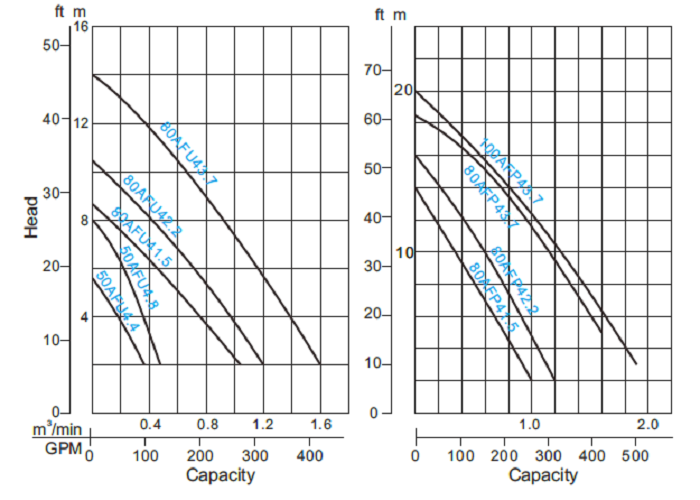

| 2P | HCP 50AFU2.4 | 0.5(0.4) | 2″ (50) | 1 | Capacitor | 5.5 | 0.15 | 18 | 40 | 19(42) | 35 | 236 | 152 | 418 |

| 3 | Direct | 18(40) | ||||||||||||

| HCP 50AFU2.8 | 1 (0.75) | 2″ (50) | 1 | Capacitor | 8 | 0.5 | 25 | 52 | 20(44) | 35 | 236 | 152 | 418 | |

| 3 | Direct | 19(42) | ||||||||||||

| HCP 80AFU21.5 | 2 (1.5) | 3″ (80) | 1 | Capacitor | 8 | 0.4 | 25 | 106 | 40(88) | 50 | 379 | 202 | 575 | |

| 3 | Direct | 36(79) | 524 | |||||||||||

| HCP 80AFU21.5L | 2 (1.5) | 3″ (80) | 1 | Capacitor | 3.5 | 0.5 | 12 | 132 | 43(95) | 76 | 402 | 217 | 626 | |

| 3 | Direct | 39(86) | 575 | |||||||||||

| HCP 80AFU22.2 | 3 (2.2) | 3″ (80) | 1 | Capacitor | 12 | 0.4 | 40 | 106 | 42(93) | 50 | 379 | 202 | 607 | |

| 3 | Direct | 38(88) | 524 | |||||||||||

| HCP 80AFU 22.2L | 3 (2.2) | 3″ (80) | 1 | Capacitor | 5.5 | 0.5 | 18 | 132 | 45(99) | 76 | 402 | 217 | 659 | |

| 3 | Direct | 41(90) | 575 | |||||||||||

| HCP 80AFU23.7 | 5 (3.7) | 3″ (80) | 1 | Capacitor | 15 | 0.5 | 15 | 132 | 56(123) | 56 | 478 | 220 | 588 | |

| 3 | Direct | |||||||||||||

| HCP 80AFP21.5 | 2 (1.5) | 3″ (80) | 1 | Capacitor | 8 | 0.6 | 25 | 158 | 42(93) | 35 | 413 | 260 | 576 | |

| 3 | Direct | 38(88) | 525 | |||||||||||

| HCP 80AFP22.2 | 3 (2.2) | 3″ (80) | 1 | Capacitor | 12 | 0.6 | 40 | 158 | 45(99) | 35 | 413 | 260 | 608 | |

| 3 | Direct | 40(158) | 525 | |||||||||||

| Item | Description | ||

| Liquid temp. | 0-40°C(32~104°F) | ||

| Applications | Wastewater • Sewage | ||

| Max depth | 30m (100 feet) | ||

| Pump sect. | Structure | Impeller | Semi-Enclosed channel |

| M. seal | Double M. seals | ||

| Bearing | Ball type | ||

| Material | Upper cover | FC-200 | |

| Casing | FC-200 | ||

| Impeller | FC-200 | ||

| M. seal | Lower Sic/Sic • Upper: CA/CE | ||

| Motor sect. | Motor | Dry motor | |

| 4P (1800RPM) | |||

| Insulation | B Class (5HP:F Cass) | ||

| Frequency | 60Hz | ||

| Aoto-cut | Auto-cut (MTP:15-20HP) | ||

| Material | Frame | FC-200 | |

| Main shaft | SUS420J2 | ||

| Cable | VCT or HO7RN-F or SJOW/SOW | ||

| Pole | Model | Power HP(kW) |

Discharge Inch(mm) |

Phase Ø |

Start Method |

Head m |

Capacity | Head feed |

Capacity GMP |

Weight kg (b) 1/3 |

Solid Passage mm |

Dimension (mm) | ||

| m³/min | Length | Width | Height | |||||||||||

| 4P | HCP 50AFU4.4 | 0.5(0.4) | 2″ (50) | 1 | Capacitor | 3.5 | 0.23 | 12 | 60 | 30(66) | 50 | 346 | 204 | 516 |

| 3 | Direct | 28(62) | ||||||||||||

| HCP 50AFU4.8 | 1 (0.75) | 2″ (50) | 1 | Capacitor | 5 | 0.3 | 15 | 80 | 31(68) | 50 | 346 | 204 | 516 | |

| 3 | Direct | 29(64) | ||||||||||||

| HCP 80AFU41.5 | 2 (1.5) | 3″ (80) | 1 | Capacitor | 5 | 0.6 | 15 | 158 | 52(115) | 76 | 500 | 256 | 700 | |

| 3 | Direct | 52(115) | 622 | |||||||||||

| HCP 80AFU42.2 | 3 (2.2) | 3″ (80) | 3 | Direct | 7 | 0.6 | 22 | 158 | 56(150) | 80 | 538 | 289 | 573 | |

| HCP 80AFU43.7 | 5 (3.7) | 3″ (80) | 3 | Direct | 10.5 | 0.6 | 35 | 158 | 75(165) | 80 | 538 | 289 | 697 | |

| HCP 80AFP41.5 | 2 (1.5) | 3″ (80) | 1 | Capacitor | 8 | 0.5 | 25 | 132 | 51(122) | 50 | 530 | 290 | 645 | |

| 3 | Direct | 51(122) | 567 | |||||||||||

| HCP 80AFP42.2 | 3 (2.2) | 3″ (80) | 3 | Direct | 10 | 0.6 | 32 | 158 | 68(150) | 50 | 553 | 313 | 623 | |

| HCP 80AFP43.7 | 5 (3.7) | 3″ (80) | 3 | Direct | 15 | 0.6 | 50 | 158 | 78(172) | 50 | 553 | 313 | 643 | |

| HCP 100AFP43.7 | 5 (3.7) | 4″ (100) | 3 | Direct | 12.5 | 1.0 | 42 | 265 | 81(179) | 50 | 570 | 313 | 643 | |

| Pole | Model | Power HP(kW) |

Discharge Inch(mm) |

Phase Ø |

Start Method |

Head m |

Capacity m³/min |

Head feed |

Capacity GMP |

Weight kg (b) 3 |

Solid Passage mm |

Dimension (mm) | ||

| Length | Width | Height | ||||||||||||

| 4P | HCP AF-55AU | 7.5(5.5) | 4″ (100) | 3 | Direct | 11 | 1.0 | 36 | 265 | 129(285) | 65 | 687 | 405 | 795 |

| HCP AF-75AU | 10 (0.75) | 4″ (100) | 3 | Direct | 14.5 | 1.0 | 48 | 265 | 143(315) | 65 | 687 | 405 | 816 | |

| HCP AF-55AE | 7.5(5.5) | 4″ (100) | 3 | Direct | 16 | 1.0 | 52 | 265 | 136(300) | 40 | 687 | 405 | 795 | |

| HCP AF-75E | 10 (0.75) | 4″ (100) | 3 | Direct | 21 | 1.0 | 70 | 265 | 150(331) | 40 | 687 | 405 | 816 | |

| HCP AF-415 | 15 (11) | 4″ (100) | 3 | Direct | 20 | 1.5 | 65 | 396 | 163(360) | 40 | 687 | 405 | 816 | |

| AF-610 | 10 (0.75) | 6″ (150) | 3 | Direct | 10 | 2.5 | 32 | 660 | 219(4830) | 73 | 888 | 449 | 870 | |

| HCP AF-615 | 15 (11) | 6″ (150) | 3 | Y – Δ | 16 | 2.5 | 52 | 660 | 259(517) | 70 | 895 | 477 | 1026 | |

| HCP AF-620 | 20 (15) | 6″ (150) | 3 | Y – Δ | 20 | 2.5 | 68 | 660 | 276(608) | 70 | 895 | 477 | 1026 | |

| HCP AF-815 | 15 (11) | 8″ (200) | 3 | Y – Δ | 8.5 | 4.5 | 28 | 1190 | 268(591) | 70 | 1045 | 497 | 1021 | |

| HCP AF-820 | 20 (15) | 8″ (200) | 3 | Y – Δ | 13 | 4.5 | 42 | 1190 | 281(620) | 70 | 1045 | 501 | 1032 | |