Submersible pumps or submersible pumps HCP Series SF / SA The pumps are stainless steel suitable for wastewater with weak acids. For industrial and wastewater treatment

ACCESSORIES :

ELBOW / GRS – GUIDE RAIL SYSTEMS

| Item | Description | |

| Limits of Use |

Liquid Temp. | 0 ̴ 40°C (32 ~ 104°F) |

| Applications | Corrosive·Food·Processing Liquids | |

| Type | Frequency | 50Hz |

| Motor | 2P(3600rpm)·Dry Motor | |

| Insulation | Class B (0.5 ~ 3HP)·Class F (5 ~ 15HP) | |

| Protection | IP68 | |

| Protector | Auto-cut (1HP 1Ø / 0.5 ~ 3Ø) Thermal (0.5HP 1Ø / 15HP 3Ø) |

|

| Bearing | Ball type | |

| M.seal | Double M.seals | |

| Impeller | Semi-open | |

| Material | Upper Cover | SCS14 |

| Motor Frame | SUS316 | |

| Shaft | SUS316(0.5 ~ 10HP)·SUS630(15HP) | |

| M.seal | CV/CE & SiC/SiC | |

| O-ring | Viton | |

| Casing | SCS14 | |

| Impeller | SCS14 | |

| Cable | VCT or H07RN-F SJOW/SOW | |

| Optional | Pump can be customized to fit specifications | |

| Model | Output HP (kW) |

Discharge Inch (mm) |

Phase Ø |

Start Method |

Head m |

Standard | Solid Passage mm |

weight kg | Dimensions mm | ||||||

| m³/min | m³/h | 10Ø | 3Ø | A | B | C | D | ||||||||

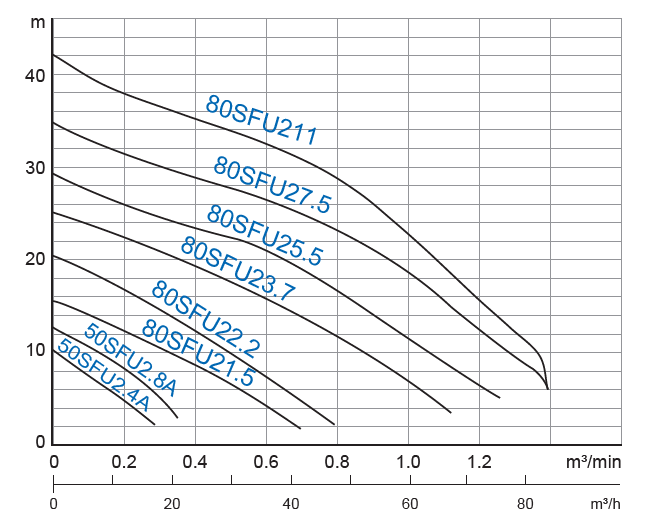

| U Type | 50SFU2.4A | 0.5(0.4) | 2″(50) | 1 | Capacitor | 6 | 0.15 | 9 | 35 | 15 | 14 | 237 | – | 153 | 433 |

| 3 | Direct | ||||||||||||||

| 50SFU2.8A | 1(0.75) | 2″(50) | 1 | Capacitor | 8 | 0.2 | 12 | 35 | 16 | 15 | 237 | – | 153 | 433 | |

| 3 | Direct | ||||||||||||||

| 80SFU21.5 | 2(1.5) | 3″(80) | 3 | Direct | 8.5 | 0.4 | 24 | 50 | – | 26.5 | 402 | 260 | 202 | 517 | |

| 80SFU22.2 | 3(2.2) | 3″(80) | 3 | Direct | 13 | 0.4 | 24 | 50 | – | 29 | 402 | 260 | 202 | 517 | |

| 80SFU23.7 | 5(3.7) | 3″(80) | 3 | Direct | 17.5 | 0.5 | 30 | 50 | – | 40 | 476 | 286 | 222 | 561 | |

| 80SFU25.5 | 7.5(5.5) | 3″(80) | 3 | Direct | 21 | 0.6 | 36 | 50 | – | 61 | 499 | 309 | 258 | 657 | |

| 80SFU27.5 | 10(7.5) | 3″(80) | 3 | Direct | 26 | 0.6 | 36 | 50 | – | 67 | 499 | 309 | 258 | 657 | |

| 80SFU211 | 15(11) | 3″(80) | 3 | S-D | 33 | 0.6 | 36 | 50 | – | 76 | 499 | 309 | 258 | 697 | |

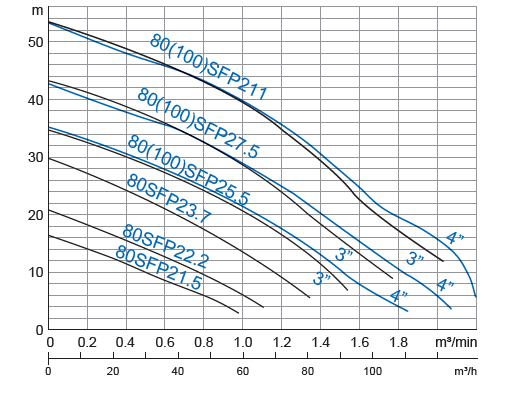

| P Type | 80SFP21.5 | 2(1.5) | 3″(80) | 3 | Direct | 8.5 | 0.6 | 36 | 35 | – | 28.5 | 417 | 275 | 260 | 521 |

| 80SFUP22.2 | 3(2.2) | 3″(80) | 3 | Direct | 13 | 0.6 | 36 | 35 | – | 31.5 | 417 | 275 | 260 | 521 | |

| 80SFP23.7 | 5(3.7) | 3″(80) | 3 | Direct | 20.5 | 0.6 | 36 | 32 | – | 43 | 495 | 305 | 290 | 568 | |

| 80(100)SFP25.5 | 7.5(5.5) | 3″(80) | 3 | Direct | 28 | 0.6 | 36 | 30 | – | 67 | 563 | 373 | 345 | 684 | |

| 4″(100) | 21.5 | 0.1 | 60 | 591 | |||||||||||

| 80(100)SFP27.5 | 10(7.5) | 3″(80) | 3 | Direct | 35.5 | 0.6 | 36 | 30 | – | 73 | 563 | 373 | 345 | 684 | |

| 4″(100) | 29 | 0.1 | 60 | 591 | |||||||||||

| 80(100)SFp211 | 15(11) | 3″(80) | 3 | S-D | 46 | 0.6 | 36 | 30 | – | 82 | 563 | 373 | 345 | 724 | |

| 4″(100) | 39.5 | 0.1 | 60 | 591 | |||||||||||