Foras Plus water pump, horizontal 304 stainless steel, protection level IP44 Can pump unclean water

Centrifugal Pump Applications

| CARATTERISTICHE COSTRUTTIVE / CONSTRUCTION FEATURES CARACTERISTICAS CONSTRUCTIVAS / CARACTERISTIQUES D’EXECUTION |

|

| Corpo pompa | acciaio cromo-nickel AISI 304 |

| Pump body | stainless steel AISI 304 |

| Cuerpo bomba | acero cromo-nickel AISI 304 |

| Corps de pompe | acier cromo-nickel AISI 304 |

| Supporto motore | alluminio |

| Motor bracket | alluminium |

| Soporte motor | alluminio |

| Support moteur | alluminium |

| Girante | Noryl® |

| Impeller | |

| Rodete | |

| Turbine | |

| Tenuta meccanica | ceramica-grafite ≤ 6 giranti |

| grafite-carburo di silico ≥ 7 giranti | |

| Mechanical seal | ceramica-grafite ≤ 6 impellers |

| graphite-silico carbide ≤ 7 impellers | |

| Sello mecanico | ceramica-grafito ≤ 6 rodetes |

| grafite-carburo de silicio ≥ 7 rodetes | |

| Garniture mecanique | ceramique-graphite ≤ 6 turbines |

| grafite-carbure de silicium ≥ 7 turbines | |

| Albero motore | acciaio cromo-nickel AISI 303 |

| Motor shaft | stainless steel AISI 303 |

| Eje motor | acero cromo-nickel AISI 303 |

| Arbre moteur | acier cromo-nickel AISI 303 |

| Temperatura del liquido | -5 – +35 °C |

| Liquid temperature | |

| Temperatura del liquido | |

| Temperature du liquide | |

| Pressione di esercizio | max 8.5 bar |

| Operating pressure | |

| Presion de trabajo | |

| Pression de fonctionnement | |

| MOTORE / MOTOR / MOTOR / MOTEUR | |

| Motore 2 poli a induzione | 3- 230/400V-50Hz |

| 1-230V-50Hz | |

| 2 pole induction motor | con termoprotettore fino a 1.85kW |

| Motor de 2 polos a induccion | with thermal protection up to 1.85kW |

| con proteccion termica hasta 1.85kW | |

| Moteur a induction a 2 poles | avec protection thermique jusqu a 1.85kW |

| Classe di isolamento | F |

| Insulation class | |

| Clase de aislamiento | |

| Classe d’isolation | |

| Grado di protezione | |

| Protection degree | IP44 |

| Grado de proteccion | |

| Protection | |

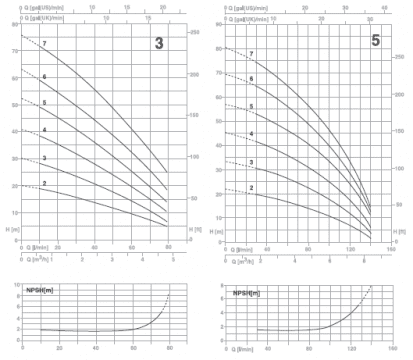

| TYPE | P2 | P1 (kW) | AMPERE | Q (m3/h-l/min) | ||||||||||

| 1~ | 3~ | 1~ | 3~ | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3.6 | 4.8 | ||||

| 0 | 10 | 20 | 30 | 40 | 60 | 80 | ||||||||

| (HP) | (kW) | 1~ | 3~ | 1×230 V (50 Hz) | 3×400 V (50 Hz) | H (m) | ||||||||

| P 3-50/2 | P 3-50/2 T | 0.5 | 0.37 | 0.45 | 0.46 | 2 | 0.9 | 20.2 | 18.8 | 17.3 | 15.3 | 13.7 | 9.5 | 4.9 |

| P 3-70/3 | P 3-70/3 T | 0.7 | 0.51 | 0.65 | 0.63 | 2.9 | 1.2 | 30 | 27.9 | 25.4 | 23 | 20.3 | 14 | 6.7 |

| P 3-90/4 | P 3-90/4 T | 0.9 | 0.66 | 0.9 | 0.88 | 4 | 1.8 | 40.8 | 38.3 | 35.1 | 31.8 | 27.9 | 19.8 | 10.4 |

| P 3-100/5 | P 3-100/5 T | 1 | 0.75 | 1.06 | 1.01 | 4.8 | 1.9 | 52.2 | 48.9 | 45.1 | 40.8 | 36 | 25.4 | 14 |

| P 3-120/6 | P 3-120/6 T | 1.2 | 0.9 | 1.23 | 1.23 | 5.6 | 2.6 | 62.8 | 58.7 | 54.5 | 49.6 | 43.9 | 32.1 | 18.3 |

| P 3-150/7 | P 3-150/7 T | 1.5 | 1.1 | 1.45 | 1.45 | 7.1 | 2.9 | 75.5 | 71.3 | 66.6 | 61.2 | 54.8 | 41.1 | 24.9 |

| TYPE | P2 | P1 (kW) | AMPERE | Q (m3/h-l/min) | |||||||||||

| 1~ | 3~ | 1~ | 3~ | 0 | 1.8 | 2.4 | 3.6 | 4.8 | 6 | 7.2 | 8.4 | ||||

| 0 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | ||||||||

| (HP) | (kW) | 1~ | 3~ | 1×230 V (50 Hz) | 3×400 V (50 Hz) | H (m) | |||||||||

| P 5-70/2 | P 5-70/2 T | 0.7 | 0.51 | 0.61 | 0.58 | 2.7 | 1.1 | 22 | 19.7 | 18.7 | 16.6 | 14 | 10.8 | 6.8 | 1.8 |

| P 5-80/3 | P 5-80/3 T | 0.8 | 0.6 | 0.86 | 0.79 | 3.9 | 1.5 | 33.4 | 30.3 | 29 | 26 | 22.5 | 17.6 | 12 | 3.9 |

| P 5-120/4 | P 5-120/4 T | 1.2 | 0.9 | 1.13 | 1.13 | 5.2 | 2.5 | 45.3 | 41.3 | 39.6 | 35.6 | 30.8 | 24.9 | 17.6 | 6.4 |

| P 5-150/5 | P 5-150/5 T | 1.5 | 1.1 | 1.47 | 1.39 | 6.8 | 2.8 | 56.8 | 53 | 51 | 46.1 | 40.1 | 33.3 | 24.8 | 11.5 |

| P 5-180/6 | P 5-180/6 T | 1.8 | 1.3 | 1.7 | 1.62 | 7.7 | 3 | 69.3 | 64.4 | 62 | 55.6 | 48.2 | 39.6 | 28.8 | 12 |

| P 5-200/7 | P 5-200/7 T | 2 | 1.5 | 2 | 1.86 | 9 | 3.4 | 80.3 | 73.6 | 71 | 64.5 | 56.1 | 46 | 33.4 | 12.5 |

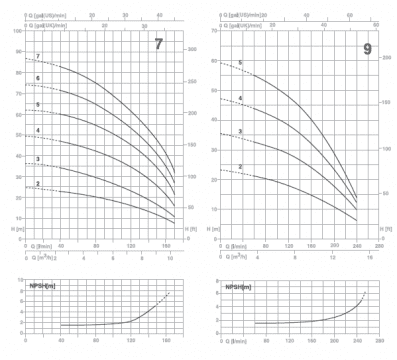

| TYPE | P2 | P1 (kW) | AMPERE | Q (m3/h-l/min) | ||||||||||||

| 1~ | 3~ | 1~ | 3~ | 0 | 2.4 | 3.6 | 4.8 | 6 | 7.2 | 8.4 | 9.6 | 10.2 | ||||

| 0 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 17 | ||||||||

| (HP) | (kW) | 1~ | 3~ | 1×230 V (50 Hz) | 3×400 V (50 Hz) | H (m) | ||||||||||

| P 7-100/2 | P 7-100/2 T | 1 | 0.75 | 0.97 | 0.9 | 4.4 | 1.7 | 24.8 | 23.4 | 22 | 20.5 | 18.7 | 16.3 | 13.6 | 10.2 | 8.3 |

| P 7-120/3 | P 7-120/3 T | 1.2 | 0.9 | 1.32 | 1.3 | 5.9 | 2.6 | 36.7 | 34 | 32 | 29.6 | 26.5 | 23 | 18.6 | 13.8 | 11 |

| P 7-180/4 | P 7-180/4 T | 1.8 | 1.3 | 1.83 | 1.71 | 8.3 | 3.2 | 49.5 | 47.4 | 45.3 | 42.5 | 39.2 | 34.8 | 29.4 | 22.6 | 16.9 |

| P 7-250/5 | P 7-250/5 T | 2.5 | 1.85 | 2.39 | 2.15 | 10.9 | 4.2 | 62.6 | 60.6 | 58.2 | 55.1 | 51.1 | 45.8 | 39 | 29.8 | 21.5 |

| P 7-300/6 | P 7-300/6 T | 3 | 2.2 | 2.68 | 2.63 | 12.2 | 5 | 74.8 | 71.5 | 68.3 | 64.5 | 59.3 | 53 | 44.6 | 34.5 | 26.7 |

| P 7-350/7 T | 3.5 | 2.57 | 3.04 | 5.5 | 87.2 | 83.3 | 79.3 | 74.6 | 68.9 | 61.9 | 52.5 | 41 | 32.2 | |||

| TYPE | P2 | P1 (kW) | AMPERE | Q (m3/h-l/min) | ||||||||||||||

| 1~ | 3~ | 1~ | 3~ | 0 | 3.6 | 4.8 | 6 | 7.2 | 8.4 | 9.6 | 10.8 | 12 | 13.2 | 14.4 | ||||

| 0 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 240 | ||||||||

| (HP) | (kW) | 1~ | 3~ | 1×230 V (50 Hz) | 3×400 V (50 Hz) | H (m) | ||||||||||||

| P 9-100/2 | P 9-100/2 T | 1 | 0.75 | 0.98 | 0.92 | 4.4 | 1.7 | 23 | 20.9 | 20 | 19.1 | 17.9 | 16.6 | 15 | 13.2 | 11.1 | 8.9 | 6.5 |

| P 9-150/3 | P 9-150/3 T | 1.5 | 1.1 | 1.43 | 1.38 | 6.7 | 2.8 | 35.2 | 32.6 | 31.5 | 30.3 | 28.8 | 26.9 | 24.5 | 21.5 | 18.3 | 14.7 | 10.8 |

| P 9-200/4 | P 9-200/4 T | 2 | 1.5 | 1.88 | 1.77 | 8.4 | 3.3 | 47.1 | 43.5 | 42 | 40.5 | 38.3 | 35.7 | 32.4 | 28.4 | 23.8 | 18.9 | 13.3 |

| P 9-250/5 | P 9-250/5 T | 2.5 | 1.85 | 2.32 | 2.18 | 10.6 | 4.3 | 59.2 | 54.4 | 52.4 | 50.4 | 47.9 | 44.8 | 40.5 | 35.5 | 29.8 | 23.5 | 16.3 |

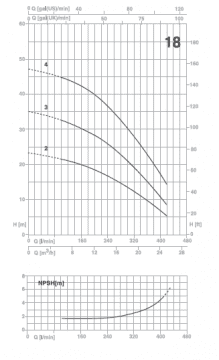

| TYPE | P2 | P1 (kW) | AMPERE | Q (m3/h-l/min) | ||||||||||||||||||

| 3~ | 3~ | 0 | 6 | 7.2 | 8.4 | 9.6 | 10.8 | 12 | 13.2 | 14.4 | 15.6 | 16.8 | 18 | 19.2 | 20.4 | 21.6 | 22.8 | 24 | 25.2 | |||

| 0 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 240 | 260 | 280 | 300 | 320 | 340 | 360 | 380 | 400 | 420 | |||||

| (HP) | (kW) | 3~ | 3×400 V (50 Hz) | H (m) | ||||||||||||||||||

| P 18-180/2 T | 1.8 | 1.3 | 1.52 | 3 | 23.1 | 21.4 | 21 | 20.5 | 19.9 | 19.2 | 18.4 | 17.6 | 16.7 | 15.7 | 14.7 | 13.5 | 12.1 | 10.9 | 9.7 | 8.3 | 7 | 5.5 |

| P 18-250/3 T | 2.5 | 1.85 | 2.19 | 4.3 | 35 | 32.7 | 32.2 | 31.4 | 30.5 | 29.5 | 28.3 | 26.7 | 25.5 | 24.3 | 22.8 | 21.2 | 19.3 | 17.3 | 15.1 | 12.9 | 10.8 | 8.7 |

| P 18-400/4 T | 4 | 3 | 2.99 | 5.5 | 47.2 | 44.6 | 44.1 | 43.3 | 42.4 | 41.2 | 40 | 38.5 | 36.7 | 34.9 | 32.9 | 30.5 | 27.9 | 25.3 | 22.7 | 20 | 17.1 | 14.3 |

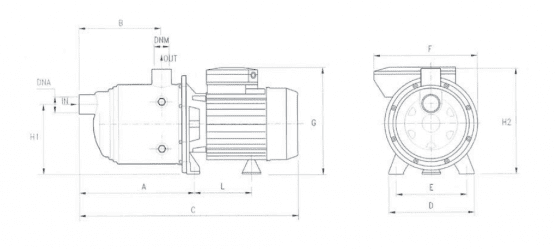

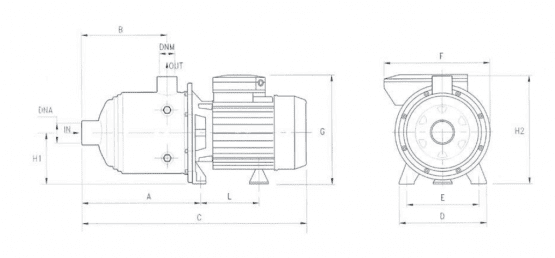

| TYPE | DIMENSIONS (mm) | Kg | DNA | DNM | |||||||||

| A | B | C | D | E | F | G | L | H1 | H2 | ||||

| P 3-50/2 | 166.8 | 103 | 333 | 164 | 140 | 178 | 190 | 93.7 | 128 | 192 | 6.3 | 1″G | 1″G |

| P 3-70/3 | 166.8 | 103 | 333 | 164 | 140 | 178 | 190 | 93.7 | 128 | 192 | 7.2 | ||

| P 3-90/4 | 190.8 | 127 | 357 | 164 | 140 | 178 | 190 | 93.7 | 128 | 192 | 8.3 | ||

| P 3-100/5 | 214.8 | 151 | 404 | 164 | 140 | 178 | 203 | 104.7 | 128 | 192 | 10.6 | ||

| P 3-120/6 | 238.8 | 175 | 428 | 164 | 140 | 178 | 203 | 104.7 | 128 | 192 | 11 | ||

| P 3-150/7 | 262.8 | 199 | 483 | 164 | 140 | 201 | 211 | 128.2 | 134 | 198 | 14.1 | ||

| P 5-70/2 | 166.8 | 103 | 333 | 164 | 140 | 178 | 195 | 93.7 | 128 | 192 | 7.1 | ||

| P 5-80/3 | 166.8 | 103 | 357 | 164 | 140 | 178 | 203 | 93.7 | 128 | 192 | 9.5 | ||

| P 5-120/4 | 190.8 | 127 | 380 | 164 | 140 | 178 | 203 | 104.7 | 128 | 192 | 11.1 | ||

| P 5-150/5 | 214.8 | 151 | 436 | 164 | 140 | 201 | 211 | 128.2 | 134 | 198 | 13.5 | ||

| P 5-180/6 | 238.8 | 175 | 459 | 164 | 140 | 201 | 211 | 128.2 | 134 | 198 | 14.4 | ||

| P 5-200/7 | 262.8 | 199 | 483 | 164 | 140 | 201 | 211 | 128.2 | 134 | 198 | 16.2 | ||

| TYPE | DIMENSIONS (mm) | Kg | DNA | DNM | |||||||||

| A | B | C | D | E | F | G | L | H1 | H2 | ||||

| P 7-100/2 | 166.8 | 103 | 356 | 164 | 140 | 178 | 203 | 104.7 | 92 | 192 | 10 | 1″1/4 G | 1″G |

| P 7-120/3 | 166.8 | 103 | 356 | 164 | 140 | 178 | 203 | 104.7 | 92 | 192 | 10.8 | ||

| P 7-180/4 | 190.8 | 127 | 411 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 13.8 | ||

| P 7-250/5 | 214.8 | 151 | 436 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 15.8 | ||

| P 7-300/6 | 238.8 | 175 | M503 | 164 | 140 | 201 | M 229 | M 148.2 | M 103 | M 203 | 18.2 | ||

| T 459 | T 211 | T 128.2 | T 98 | T 198 | |||||||||

| P 7-350/7 | 262.8 | 199 | 527 | 164 | 140 | 201 | 229 | 104.7 | 103 | 203 | 18.6 | ||

| P 9-100/2 | 185.8 | 118 | 375 | 164 | 140 | 178 | 203 | 128.2 | 98 | 192 | 10.1 | 1″1/2 G | 1*1/4 G |

| P 9-150/3 | 185.8 | 118 | 375 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 13.2 | ||

| P 9-200/4 | 215.8 | 148 | 436 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 15.5 | ||

| P 9-250/5 | 245.8 | 178 | 464 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 16.1 | ||

| P 18-180/2 T | 201 | 141 | 432 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 12.9 | 2″G | 1″1/2 G |

| P 18-250/3 T | 238.5 | 141 | 432 | 164 | 140 | 201 | 211 | 128.2 | 98 | 198 | 14.5 | ||

| P 18-400/4 T | 276 | 178.5 | 514 | 164 | 140 | 201 | 229 | 148.2 | 103 | 203 | 20.8 | ||