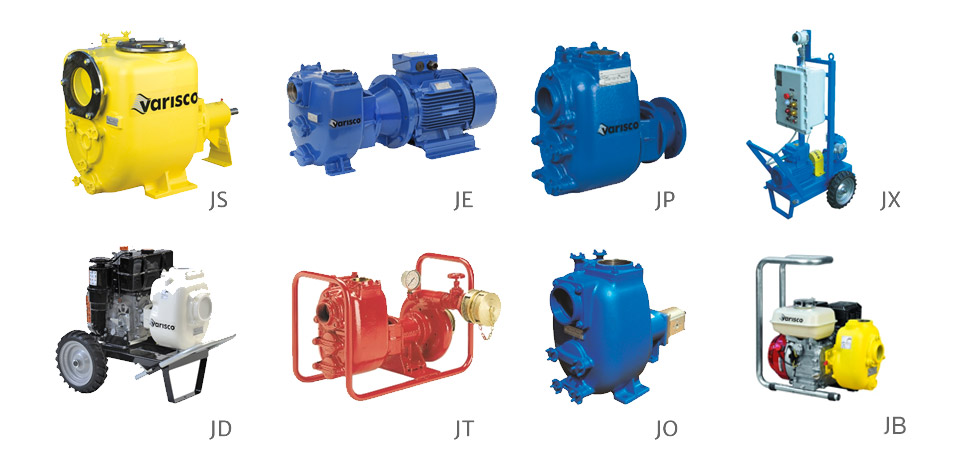

Self-priming Centrifugal Pumps VARISCO J Series is durable and long-lasting

VARISCO J Series APPLICATIONS

INDUSTRY

CIVIL ENGINEERING

SAFETY

VARISCO J Series FEATURES

Rapid self-priming

without foot valve. Once filled with water, the pump is automatically primed to a height of 7.5 m

Specifications VARISCO J Series

| Model | Ports | Solids | 50 HZ | |||||||||

| Capacity | Head | Speed | Power | |||||||||

| New | Old | mm | in | mm | m3/h | m | rpm | kW | ||||

| J 1-110 * | J 40 | 40 | 1”1/2 | 20 | 22 | 15 | 5 | 5,5 | 11 | 15 | 2900 | 1,1 |

| J 1-160 | E 30-160 | 40 | 1”1/2 | 8 | 20 | 12 | 5 | 10 | 24 | 27 | 2900 | 2,2 |

| J 1-180 * | 40 | 1”1/2 | 11 | 25 | 15 | 6 | 22 | 32 | 34 | 2900 | 4 | |

| J 2-100 * | E 50 | 50 | 2” | 17 | 30 | 20 | 8 | 2 | 8 | 13 | 2900 | 1,1 |

| J 2-120 * | J 50 | 50 | 2” | 25 | 44 | 30 | 10 | 5 | 12 | 18 | 2900 | 2,2 |

| J 2-170 * | 50 | 2” | 13 | 44 | 30 | 10 | 14 | 22 | 31 | 2900 | 4 | |

| J 2-180 * | 50 | 2” | 15 | 50 | 30 | 10 | 20 | 30 | 24 | 2900 | 5,5 | |

| J 2-220 | J 60-220 | 50 | 2” | 12 | 42 | 28 | 10 | 42 | 52 | 58 | 2900 | 11 |

| J 3-100 * | E 75 | 80 | 3” | 25 | 60 | 37 | 15 | 4 | 9 | 12 | 2900 | 2,2 |

| J 3-140 | 80 | 3” | 28 | 70 | 40 | 20 | 13 | 18 | 20 | 2900 | 4 | |

| J 3-225 | 80 | 3” | 23 | 80 | 50 | 20 | 40 | 48 | 53 | 2900 | 15 | |

| J 3-240 | 80 | 3″ | 14 | 70 | 40 | 15 | 44 | 60 | 66 | 2900 | 18,5 | |

| J 4-100 * | E 100 | 100 | 4” | 38 | 100 | 65 | 25 | 5 | 9 | 13 | 2900 | 4 |

| J 4-159 | J 90-2 | 100 | 4” | 45 | 155 | 100 | 40 | 13 | 26 | 26 | 2900 | 15 |

| J 4-160 * | J 90-4 | 100 | 4” | 45 | 150 | 100 | 40 | 12 | 22 | 24 | 2900 | 11 |

| J 3-210 | J 85 | 80 | 3” | 40 | 80 | 45 | 20 | 7 | 13 | 15 | 1450 | 4 |

| J 4-250 * | 100 | 4” | 50 | 150 | 80 | 40 | 7 | 15 | 18 | 1450 | 7,5 | |

| J 4-253 * | J 4-250W | 100 | 4” | 45 | 150 | 100 | 40 | 9 | 15 | 19 | 1450 | 7,5 |

| J 4-316 | 100 | 4” | 38 | 180 | 110 | 60 | 16 | 26 | 29 | 1450 | 18,5 | |

| J 6-250 * | 150 | 6” | 76 | 300 | 200 | 80 | 5 | 11 | 15 | 1450 | 11 | |

| J 6-253 * | J 6-250W | 150 | 6” | 45 | 300 | 200 | 80 | 4 | 10 | 14 | 1450 | 11 |

| J 6-350 | 150 | 6” | 37 | 300 | 180 | 80 | 19 | 30 | 33 | 1450 | 30 | |

| J 6-355 | 150 | 6” | 47 | 330 | 200 | 90 | 14 | 26 | 32 | 1450 | 30 | |

| J 6-400 | 150 | 6” | 50 | 380 | 200 | 80 | 18 | 36 | 38 | 1450 | 45 | |

| J 8-300 | 200 | 8” | 60 | 480 | 320 | 120 | 8 | 15 | 20 | 1450 | 22 | |

| J 8-305 | 200 | 8” | 76 | 420 | 200 | 100 | 5 | 13 | 17 | 1450 | 18,5 | |

| J 10-305 | 250 | 10” | 76 | 600 | 400 | 200 | 6 | 15 | 18,5 | 1450 | 30 | |

| J 6-350 | 150 | 6” | 37 | 280 | 200 | 80 | 3 | 9 | 14 | 960 | 11 | |

| J 6-355 | 150 | 6” | 47 | 225 | 150 | 75 | 5 | 10 | 14 | 960 | 11 | |

| J 12-400 | J 300 | 300 | 12” | 70 | 1200 | 720 | 300 | 8 | 12 | 15 | 960 | 55 |

| Model | Ports | Solids | 60 HZ | |||||||||

| Capacity | Head | Speed | Power | |||||||||

| New | Old | mm | in | mm | m3/h | m | rpm | kW | ||||

| J 1-110 * | J 40 | 40 | 1”1/2 | 20 | 24 | 15 | 5 | 5 | 18 | 21,5 | 3450 | 2,2 |

| J 1-160 | E 30-160 | 40 | 1”1/2 | 8 | 21 | 13 | 5 | 12 | 35 | 39 | 3450 | 4 |

| J 1-180 * | 40 | 1”1/2 | 11 | 25 | 15 | 6 | 34 | 48 | 48 | 3450 | 5,5 | |

| J 2-100 * | E 50 | 50 | 2” | 17 | 32 | 20 | 8 | 5 | 13 | 18 | 3450 | 2,2 |

| J 2-120 * | J 50 | 50 | 2” | 25 | 48 | 30 | 10 | 9,5 | 20 | 25 | 3450 | 4 |

| J 2-170 * | 50 | 2” | 13 | 48 | 30 | 10 | 22 | 37 | 47 | 3450 | 7,5 | |

| J 2-180 * | 50 | 2” | 15 | 50 | 30 | 10 | 34 | 44 | 48 | 3450 | 11 | |

| J 2-220 | J 60-220 | 50 | 2” | 12 | – | – | – | – | – | – | – | – |

| J 3-100 * | E 75 | 80 | 3” | 25 | 70 | 43 | 15 | 5 | 13 | 17 | 3450 | 3 |

| J 3-140 | 80 | 3” | 28 | 70 | 40 | 20 | 21 | 26 | 28,5 | 3450 | 7,5 | |

| J 3-225 | 80 | 3” | 23 | – | – | – | – | – | – | – | – | |

| J 3-240 | 80 | 3″ | 14 | – | – | – | – | – | – | – | – | |

| J 4-100 * | E 100 | 100 | 4” | 38 | 120 | 75 | 30 | 6 | 14 | 18 | 3450 | 7,5 |

| J 4-159 | J 90-2 | 100 | 4” | 45 | – | – | – | – | – | – | – | – |

| J 4-160 * | J 90-4 | 100 | 4” | 45 | – | – | – | – | – | – | – | – |

| J 3-210 | J 85 | 80 | 3” | 40 | 90 | 45 | 20 | 12 | 19,5 | 22 | 1750 | 7,5 |

| J 4-250 * | 100 | 4” | 50 | 150 | 80 | 40 | 14 | 24 | 26,5 | 1750 | 15 | |

| J 4-253 * | J 4-250W | 100 | 4” | 45 | 150 | 100 | 40 | 18 | 24 | 28 | 1750 | 15 |

| J 4-316 | 100 | 4” | 38 | 180 | 110 | 60 | 30 | 40 | 43 | 1750 | 30 | |

| J 6-250 * | 150 | 6” | 76 | 340 | 200 | 80 | 8 | 18 | 22 | 1750 | 22 | |

| J 6-253 * | J 6-250W | 150 | 6” | 45 | 340 | 200 | 80 | 8 | 17 | 20 | 1750 | 18,5 |

| J 6-350 | 150 | 6” | 37 | – | – | – | – | – | – | – | – | |

| J 6-355 | 150 | 6” | 47 | – | – | – | – | – | – | – | – | |

| J 6-400 | 150 | 6” | 50 | 380 | 200 | 100 | 42 | 54 | 55 | 1750 | 75 | |

| J 8-300 | 200 | 8” | 60 | 480 | 320 | 120 | 15 | 25 | 28,5 | 1750 | 45 | |

| J 8-305 | 200 | 8” | 76 | 480 | 200 | 100 | 10 | 20 | 27 | 1750 | 30 | |

| J 10-305 | 250 | 10” | 76 | 600 | 400 | 200 | 17 | 23,5 | 28 | 1750 | 45 | |

| J 6-350 | 150 | 6” | 37 | – | – | – | – | – | – | – | – | |

| J 6-355 | 150 | 6” | 47 | 280 | 200 | 80 | 7 | 14 | 20 | 1150 | 15 | |

| J 12-400 | J 300 | 300 | 12” | 70 | – | – | – | – | – | – | – | – |

Engine-driven pumps

| Model |

Ports |

Solids |

Capacity |

Head |

Speed |

Power |

||

|

New |

Old |

mm |

in |

mm |

m3/h |

m |

rpm |

kW |

| J 1-110 | J 40 |

40 |

1”1/2 |

20 |

25 |

25 |

3600 |

2,6 |

| J 1-160 | E 30-160 |

40 |

1”1/2 |

8 |

22 |

48 |

3600 |

5,5 |

| J 1-180 |

40 |

1”1/2 |

11 |

26 |

48 |

3200 |

5,3 |

|

| J 2-100 | E 50 |

50 |

2” |

17 |

39 |

22 |

3600 |

3 |

| J 2-120 | J 50 |

50 |

2” |

25 |

48 |

28 |

3600 |

4,1 |

| J 2-170 |

50 |

2” |

13 |

50 |

36 |

3000 |

5,5 |

|

| J 2-180 |

50 |

2” |

15 |

50 |

40 |

3000 |

5,5 |

|

| J 2-220 | J 60-220 |

50 |

2” |

12 |

41 |

60 |

3000 |

10,3 |

| J 3-100 | E 75 |

80 |

3” |

25 |

75 |

22 |

3000 |

5 |

| J 3-140 |

80 |

3” |

28 |

80 |

25 |

3000 |

5,5 |

|

| J 3-225 |

80 |

3” |

23 |

120 |

60 |

3000 |

24 |

|

| J 3-240 |

80 |

3” |

14 |

70 |

78 |

3000 |

26 |

|

| J 4-100 | E 100 |

100 |

4” |

38 |

130 |

24 |

3600 |

8 |

| J 4-159 | J 90-2 |

100 |

4” |

45 |

170 |

23 |

2500 |

12 |

| J 4-160 | J 90-4 |

100 |

4” |

45 |

160 |

21 |

2500 |

12 |

| J 5-180 | J 120-2 |

125 |

5” |

60 |

230 |

17 |

2000 |

14 |

| J 3-210 | J 85 |

80 |

3” |

40 |

90 |

25 |

1800 |

8,1 |

| J 4-250 |

100 |

4” |

50 |

160 |

32 |

1800 |

20 |

|

| J 4-253 | J 4-250W |

100 |

4” |

45 |

150 |

29 |

1800 |

20 |

| J 4-316 |

100 |

4” |

38 |

190 |

48 |

1800 |

41 |

|

| J 6-250 |

150 |

6” |

76 |

360 |

28 |

1800 |

22 |

|

| J 6-253 | J 6-250W |

150 |

6” |

45 |

340 |

23 |

1800 |

22 |

| J 6-350 |

150 |

6” |

37 |

330 |

40 |

1500 |

27,5 |

|

| J 6-355 |

150 |

6” |

47 |

340 |

37 |

1500 |

27,5 |

|

| J 6-400 |

150 |

6” |

50 |

400 |

62 |

1800 |

81 |

|

| J 8-300 |

200 |

8” |

60 |

550 |

30 |

1800 |

41 |

|

| J 8-305 |

200 |

8” |

76 |

530 |

28 |

1800 |

32 |

|

| J 10-305 |

250 |

10” |

76 |

750 |

25 |

1700 |

40 |

|

| J 12-400 | J 300 |

300 |

12” |

70 |

1400 |

21 |

1150 |

110 |

Bare shaft

| Model |

Ports |

B |

H |

L |

D |

Weight |

|

|

mm |

in |

mm |

mm |

mm |

mm |

||

|

J 1-110 |

40 |

1″1/2 |

171 |

227 |

364 |

19 |

15 |

|

J 1-110 K |

40 |

1″1/2 |

179 |

220 |

349 |

19 |

18 |

|

J 1-160 |

40 |

1″1/2 |

241 |

279 |

383 |

19 |

22 |

|

J 1-180 |

40 |

1″1/2 |

269 |

328 |

495 |

28 |

44 |

|

J 2-100 |

50 |

2″ |

204 |

268 |

317 |

19 |

14 |

|

J 2-120 |

50 |

2″ |

188 |

328 |

429 |

19 |

25 |

|

J 2-120 K |

50 |

2″ |

219 |

286 |

407 |

19 |

27 |

|

J 2-170 |

50 |

2″ |

298 |

388 |

554 |

28 |

60 |

|

J 2-180 |

50 |

2″ |

298 |

388 |

554 |

28 |

60 |

|

J 2-220 |

50 |

2″ |

402 |

405 |

556 |

28 |

56 |

|

J 3-100 |

80 |

3″ |

230 |

307 |

354 |

19 |

17 |

|

J 3-140 |

80 |

3″ |

264 |

400 |

549 |

28 |

42 |

|

J 3-140 B |

80 |

3″ |

278 |

412 |

532 |

28 |

43 |

|

J 3-225 |

80 |

3″ |

316 |

404 |

623 |

28 |

75 |

|

J 3-240 |

80 |

3″ |

393 |

452 |

651 |

32 |

90 |

|

J 4-100 |

100 |

4″ |

283 |

382 |

468 |

19 |

35 |

|

J 4-159 |

100 |

4″ |

299 |

474 |

627 |

28 |

75 |

|

J 4-160 |

100 |

4″ |

299 |

474 |

627 |

28 |

75 |

|

J 3-210 |

80 |

3″ |

316 |

419 |

629 |

28 |

75 |

|

J 4-250 |

100 |

4″ |

421 |

497 |

759 |

32 |

130 |

|

J 4-253 |

100 |

4″ |

421 |

497 |

759 |

32 |

130 |

|

J 4-316 |

100 |

4″ |

531 |

585 |

883 |

42 |

172 |

|

J 4-316 K |

100 |

4″ |

535 |

650 |

928 |

42 |

218 |

|

J 6-250 |

150 |

6″ |

475 |

619 |

872 |

32 |

203 |

|

J 6-253 |

150 |

6″ |

475 |

619 |

872 |

32 |

203 |

|

J 6-350 |

150 |

6″ |

578 |

684 |

895 |

40 |

280 |

|

J 6-355 |

150 |

6″ |

578 |

684 |

895 |

40 |

280 |

|

J 6-400 |

150 |

6″ |

730 |

821 |

1095 |

55 |

406 |

|

J 8-300 |

200 |

8″ |

591 |

734 |

1089 |

42 |

296 |

|

J 8-305 |

200 |

8″ |

591 |

734 |

1089 |

42 |

296 |

|

J 10-305 |

250 |

10″ |

758 |

942 |

1292 |

55 |

550 |

|

J 12-400 |

300 |

12″ |

920 |

1200 |

1170 |

60 |

710 |

Close-coupled to custom design electric motor

| Model |

Ports |

B |

H |

L |

Weight |

|

|

mm |

in |

mm |

mm |

mm |

||

| J 2-220 |

50 |

2″ |

402 |

405 |

700 |

105 |

| J 3-140 |

80 |

3″ |

283 |

400 |

684 |

65 |

| J 3-210 |

80 |

3″ |

316 |

419 |

690 |

95 |

| J 4-316 G |

100 |

4″ |

531 |

585 |

1066 |

349 |

| J 4-316 K |

100 |

4″ |

535 |

650 |

1097 |

347 |

| J 6-350 |

150 |

6″ |

578 |

684 |

1095 |

275 |

| J 6-355 |

150 |

6″ |

578 |

684 |

1095 |

275 |

| J 8-300 |

200 |

8″ |

591 |

734 |

1238 |

427 |

| J 8-305 |

200 |

8″ |

591 |

734 |

1238 |

427 |

| J 10-305 |

250 |

10″ |

768 |

942 |

1481 |

780 |

Close-coupled to B34/B35 standard electric motor

| Model |

Ports |

B |

H |

L |

Weight |

|

|

mm |

in |

mm |

mm |

mm |

||

|

J 1-110 |

40 |

1″1/2 |

160 |

237 |

496 |

29 |

|

J 1-160 |

40 |

1″1/2 |

241 |

287 |

584 |

39 |

|

J 1-180 |

40 |

1″1/2 |

304 |

321 |

694 |

71 |

|

J 2-100 |

50 |

2″ |

204 |

262 |

504 |

27 |

|

J 2-120 |

50 |

2″ |

193 |

291 |

601 |

41 |

|

J 2-170 |

50 |

2″ |

345 |

404 |

859 |

96 |

|

J 2-180 |

50 |

2″ |

345 |

404 |

859 |

96 |

|

J 3-100 |

80 |

3″ |

230 |

307 |

603 |

37 |

|

J 3-140 |

80 |

3″ |

305 |

384 |

754 |

75 |

|

J 3-240 |

80 |

3″ |

393 |

452 |

1075 |

255 |

|

J 4-160 |

100 |

4″ |

299 |

465 |

1047 |

191 |

|

J 4-250 |

100 |

4″ |

421 |

490 |

981 |

186 |

|

J 4-253 |

100 |

4″ |

421 |

490 |

981 |

186 |

|

J 6-250 |

150 |

6″ |

475 |

590 |

1242 |

279 |

|

J 6-253 |

150 |

6″ |

475 |

590 |

1242 |

279 |

Engine driven pumps

| Model |

Ports |

B |

H |

L |

Weight |

|

|

mm |

in |

mm |

mm |

mm |

||

|

J 1-110 |

40 |

1″1/2 |

610 |

700 |

700 |

80 |

|

J 1-160 |

40 |

1″1/2 |

610 |

675 |

870 |

60 |

|

J 1-180 |

40 |

1″1/2 |

610 |

700 |

700 |

110 |

|

J 2-100 |

50 |

2″ |

420 |

570 |

980 |

58 |

|

J 2-120 |

50 |

2″ |

610 |

700 |

700 |

85 |

|

J 2-170 |

50 |

2″ |

720 |

1100 |

920 |

125 |

|

J 2-180 |

50 |

2″ |

720 |

1100 |

920 |

125 |

|

J 2-220 |

50 |

2″ |

800 |

952 |

1250 |

220 |

|

J 3-100 |

80 |

3″ |

420 |

570 |

980 |

69 |

|

J 3-140 |

80 |

3″ |

720 |

1100 |

920 |

130 |

|

J 3-240 |

80 |

3″ |

690 |

1470 |

1710 |

450 |

|

J 4-100 |

100 |

4″ |

610 |

730 |

700 |

108 |

|

J 4-159 |

100 |

4″ |

780 |

1170 |

1150 |

230 |

|

J 5-180 |

125 |

5″ |

1468 |

1247 |

1450 |

345 |

|

J 3-210 |

80 |

3″ |

780 |

1150 |

1270 |

270 |

|

J 4-250 |

100 |

4″ |

1468 |

1605 |

1845 |

610 |

|

J 4-253 |

100 |

4″ |

1468 |

1605 |

1845 |

610 |

|

J 4-316 |

100 |

4″ |

1368 |

1490 |

2138 |

745 |

|

J 6-250 |

150 |

6″ |

1368 |

1587 |

1753 |

710 |

|

J 6-253 |

150 |

6″ |

1368 |

1587 |

17532 |

710 |

|

J 6-350 |

150 |

6″ |

1460 |

1632 |

2528 |

955 |

|

J 6-355 |

150 |

6″ |

1460 |

1632 |

2528 |

955 |

|

J 6-400 |

150 |

6″ |

1604 |

1706 |

2828 |

1450 |

|

J 8-300 |

200 |

8″ |

1468 |

1632 |

1853 |

920 |

|

J 8-305 |

200 |

8″ |

1468 |

1632 |

1853 |

920 |

|

J 10-305 |

250 |

10″ |

1604 |

1677 |

2933 |

1340 |

|

J 12-400 |

300 |

12″ |

1814 |

1720 |

2933 |

2060 |