Submersible Sewage Pump Kira NP Series

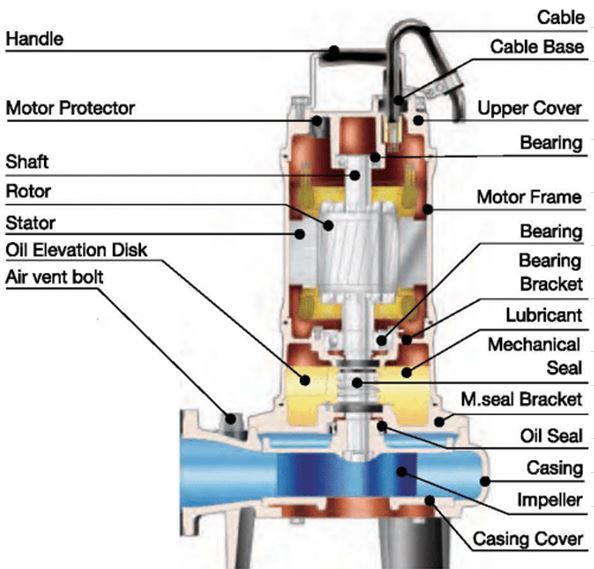

High Efficiency Dry Motor

All stator coils insulated by quality vanish under the automatic production line. This ensures the best insulation and durability.

Mechanical Seal

All pump are equipped with double mechanical seal Strong abrasion resistant mechanical seal composes of best grade silicon carbide to ensure the best seal performance.

Epoxy Cable Base

All cables are seals firmly by rubber cup and filled with thick layer of epoxy resin at the cable entry This epoxy resin prevents moisture entering through cable into motor caused by suction force in motor chamber.

Oil Lifter

An oil lifter is used in oil chamber to ensure continuous lubrication. This special parts prevent oil deficiency and burnt mechanical seal from whirlpool effect during pump operates. Not only it extend seal life, it helps cooling down shaft and give longer life of pump.

High Solids Epoxy Coating

Food Grade Lubricant

All pump are filled with non-toxic lubricant to follow company philosophy “JUNSUI” or pure water for good environment. This lubricant is food grade FDA standard, eco friendly and low impact on aquaculture farming.

Cooling Jacket

Bearing Temperature Sensor (BTS)

To level up the extra care of pump, special sensor can be placed to monitor temperature of bearing. BTS must be connected to indicator of temperature control in control box. When temp of bearing exceeds the pre-setting temp of indicator of temperature control, the relay switch will cut off power supply.

Motor Protector

The motor protector will be activated and cut power off automatically when motor run in abnormal electric current or temperature. This auto-cut protector will be self reset the motor when it returns to normal. The auto-cut protector is installed in the motor and no outside connection required. It is standard equipment in pump up to 7.5 kW. From 11 kW and up, motor thermal sensor (MTS) is applied. It is embedded in each phase of stator winding. When abnormal temperature is detected, this sensor will trip and relay switch in control box will cut off the power supply.

Moisture Sensor (MS)

This special electrode sensor will detect water leakage into oil chamber. Its purpose is to prevent mechanical seal damage or burnt from lack of lubrication ability. When water leakage is detected, the relay switch in control box will cut off power supply. This parts is standard component in pump from 11 kW.

Non-clog impeller

This useful parts will allow continuous operation of pump even in very dirty water. Pump contains semi-open or enclosed impeller having enough space to pass solid matters to minimize clogging. This usefully extend the life of pump.

YOTUBE: YONGHONG